Dissolving Waste, Delivering Innovation: The Rise of Water-Soluble Films

In an age of growing environmental awareness and sustainable innovation, water-soluble film (WSF) has emerged as a groundbreaking material in various industries. Made from polyvinyl alcohol (PVA) and other biodegradable compounds, water-soluble film dissolves completely in water, leaving behind no waste or residue. This unique characteristic makes it ideal for applications where hygiene, convenience, and eco-friendliness are top priorities. From agriculture to healthcare, the use of water soluble film is rapidly expanding as industries seek smarter, greener packaging solutions.

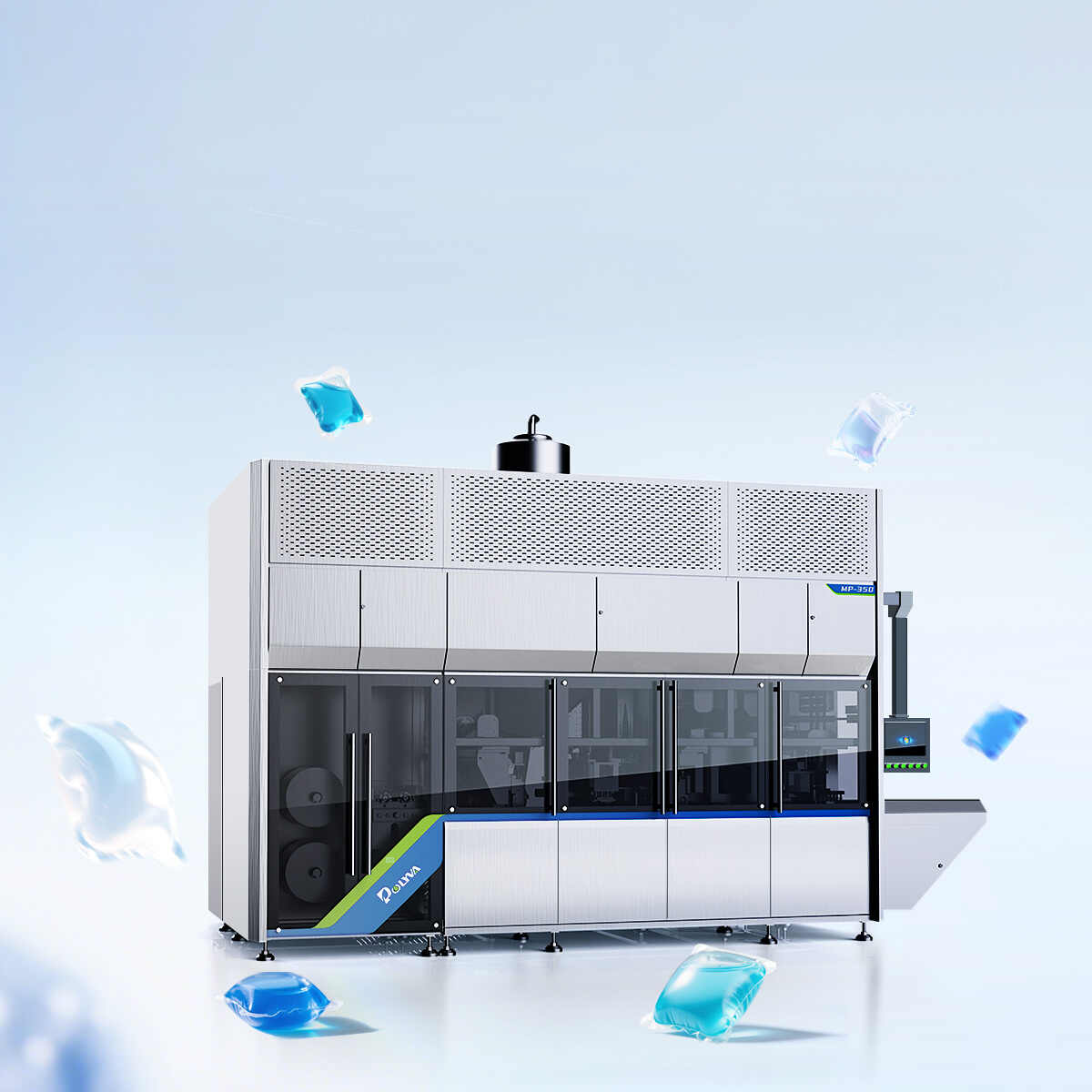

One of the most common uses of water-soluble films is in the packaging of detergents and cleaning agents. Laundry pods, dishwasher capsules, and industrial cleaning sachets are often wrapped in WSF that dissolves in water during use. This not only eliminates the need for plastic packaging but also allows for accurate dosing and mess-free handling. Consumers appreciate the convenience, while manufacturers benefit from reduced material costs and enhanced product appeal. These films are safe, non-toxic, and completely soluble even in cold water.

The healthcare and pharmaceutical industries have also found major advantages in water-soluble film technology. WSF is used in unit-dose packaging for disinfectants, surgical detergents, and controlled drug delivery systems. Medical professionals value the hygienic benefits of single-use packaging, which helps prevent contamination and ensures safe disposal. In hospitals and laboratories, WSF liners are also used in laundry bags for infectious linens—these dissolve during the wash cycle, minimizing the risk of exposure to pathogens.

Water Soluble Film Supplier is also gaining ground in agriculture, especially in the packaging of fertilizers, pesticides, and seed coatings. Farmers can use pre-measured, soluble pouches that dissolve in water during application, reducing direct contact with chemicals and improving accuracy in dosage. This method not only enhances worker safety but also lowers environmental runoff and packaging waste. As precision agriculture becomes more advanced, WSF-based solutions are helping streamline operations and support eco-friendly farming practices.

The food industry is exploring the use of edible or water-soluble films for packaging individual portions of ingredients such as spices, sauces, or nutritional supplements. These films can be consumed along with the contents or dissolved in cooking, offering both sustainability and convenience. Additionally, WSF is being developed for single-use utensils and straws that dissolve in hot water—providing a novel way to reduce plastic waste in restaurants and catering services. Although still in early stages, such innovations represent the future of sustainable packaging.

In conclusion, water-soluble film represents a powerful shift toward sustainable and efficient material solutions. Its ability to dissolve safely in water without leaving behind harmful residues makes it a preferred choice for industries aiming to reduce plastic usage and enhance user safety. As technology advances and global sustainability goals become more urgent, the demand for WSF will only continue to rise. Whether in homes, hospitals, farms, or factories, water-soluble film is dissolving boundaries—and helping build a cleaner, smarter world.

Comments

Post a Comment